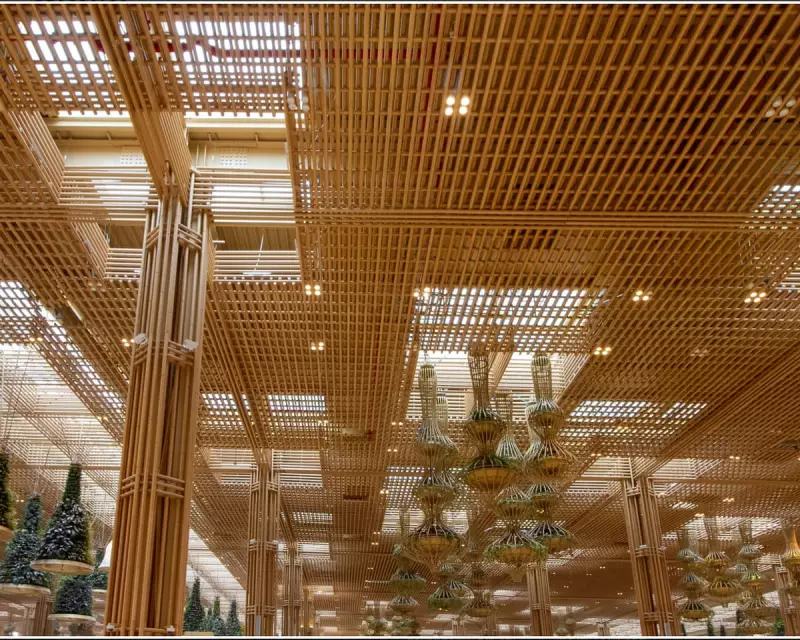

Terminal 2 of Kempegowda International Airport in Bengaluru, India, features a striking design with bamboo tubes forming its ceiling and pillars. This innovative use of bamboo is part of a broader push by engineers to promote the material as a viable and eco-friendly alternative in the construction industry.

Engineers Advocate for 'Bamboo-Ready' Design in New Manual

This week, the Institution of Structural Engineers has issued a call for architects to become 'bamboo-ready' by publishing a comprehensive manual for designing permanent structures with bamboo. The initiative aims to foster low-carbon construction and position bamboo as a serious contender to traditional materials like steel and concrete.

For many years, bamboo has been primarily associated with the diet of giant pandas, but a growing group of engineers argue it's time to recognise its potential in building. The manual seeks to bridge knowledge gaps that have historically limited bamboo's application, partly due to colonial influences on technical education.

Global Examples Showcase Bamboo's Versatility

Bamboo is already making waves in boundary-pushing projects worldwide. In addition to the airport in India, the Ninghai bamboo tower in north-east China stands over 20 metres tall, claiming the title of the world's first high-rise building made from engineered bamboo.

At the Green School in Bali, Indonesia, a bamboo arc serves as a gymnasium, demonstrating how the material can reshape sustainable architecture. In countries like Colombia and the Philippines, composite bamboo shear walls have proven resilient against earthquakes and extreme weather, supporting disaster-resilient housing built with locally sourced materials.

Addressing Carbon Emissions in Construction

The construction industry was responsible for one-third of global carbon emissions in 2022, with more than half stemming from cement and cementitious materials. As urbanisation intensifies, increasing demand for housing and infrastructure, the sector faces the challenge of meeting these needs while adhering to net zero targets.

Bamboo offers a promising solution due to its fast growth rate of about three to six years, compared to timber which takes decades. Larger varieties are particularly suited for building purposes. Neil Thomas, director of UK-based structural engineering firm Atelier One, which worked on the Green School project, stated: 'Everything you can do with timber, you can do with bamboo.'

Empowering Local Resources and Future Generations

David Trujillo, lead author of the manual and an assistant professor in humanitarian engineering at the University of Warwick, expressed hope that the guide will 'empower engineers to use their local resources' such as bamboo. While bamboo is readily available in tropical and subtropical climates, changes in the Mediterranean climate have enabled larger varieties to be grown as a crop in Portugal, potentially expanding its use in Europe.

Thomas believes bamboo can inspire architects and engineers seeking low-carbon materials. Although not suitable for buildings exceeding two storeys, Trujillo noted that bamboo-constructed buildings act as carbon stores and that harvesting the crop can aid in recovering soil degraded by monocultures. Additionally, growing bamboo requires minimal pesticides or fertilisers.

Trujillo added: 'The idea that we can move people away from using carbon-intensive materials and towards low-carbon materials or, better still, carbon-fixing materials seems like a very wise way of minimising the emissions from urbanisation.' He hopes the manual will encourage lecturers worldwide to incorporate bamboo into their curricula, educating the next generation of engineers and architects to be 'bamboo-ready'.